Ladies and gentleman, maybe a spring doesn't look sexy, slim and sleek like the French sounding "Belleville" but the "spring" is the number one solution.

We have always manufactured regulators with both Belleville spring washers and coil compression springs because both have their place in regulator manufacturing and both are best practice for different applications and specification of regulator.

We use Belleville washers for both "small regulators" and "very high pressure regulators", when neither size and or pressure is the first design consideration, then the best practice is a "coil compression spring".

For most small scale manufactures, the cost of using a specialist coil compression spring would be prohibitive so they use the much cheaper Belleville spring washers. 20 Belleville washers, purchased in bulk to make a regulator costs about 1/5th of the price of a coil compression spring that we use.

Designing our "simple" coil compression spring and getting it manufactured took over 6 months of painful work. From tracking down one of only two companies in the UK capable of manufacturing such a spring (to the specification we require) to the purchase and delivery of a minimum quantity of the worlds very finest quality spring steel wire from Sweden.

To us all it just looks like a spring but it is one of the highest specification small springs you will ever come across.

Why is a spring superior in this working environment?

The "spring" is a free standing piece and so does not suffer from a number of issues associated with Belleville washer spring stacks.

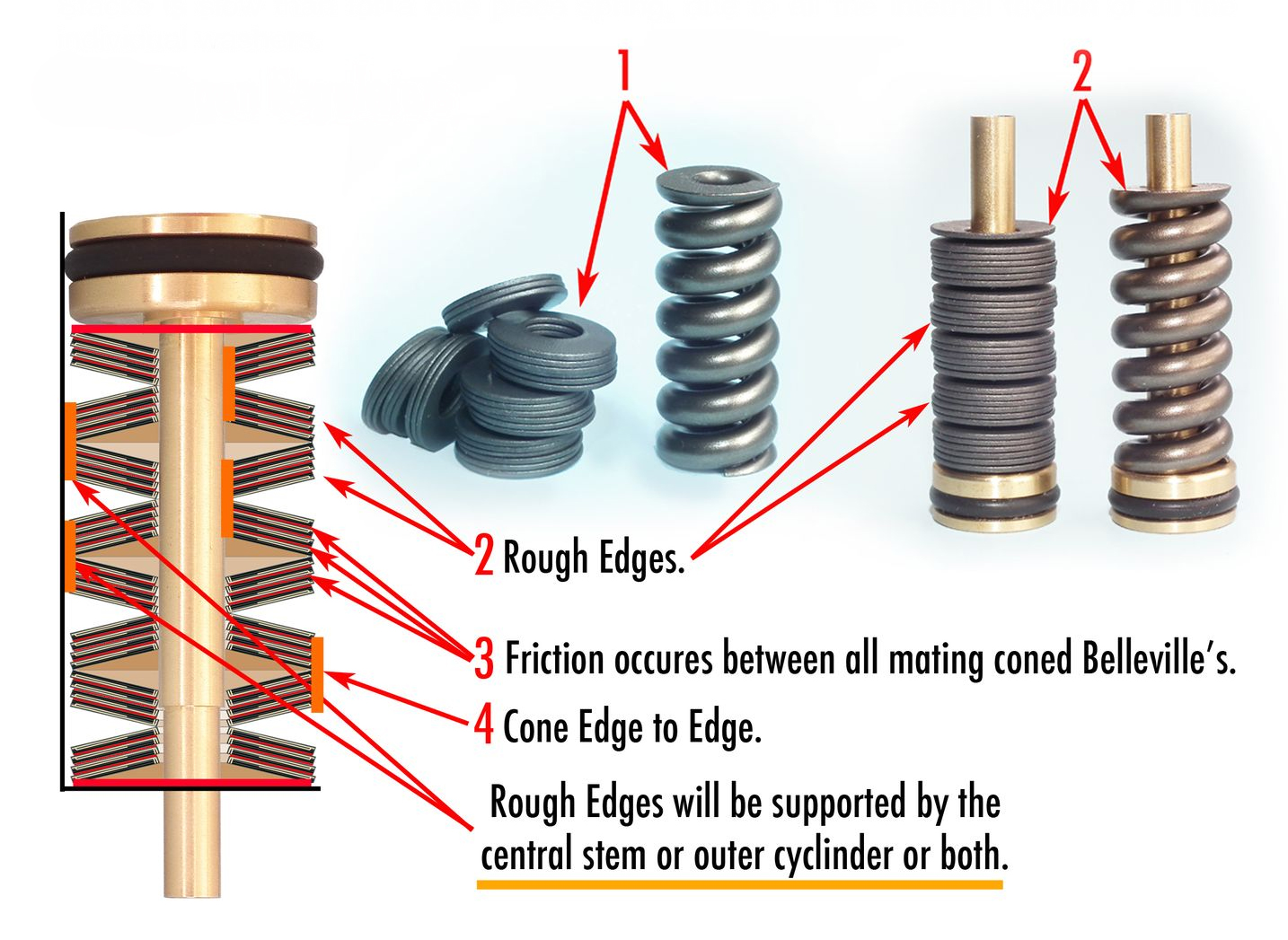

A coil compression spring is self standing / supporting and only has friction distributed across its very end faces. Belleville stacks need to be supported as they twist under load and so, will rub on either the central supporting stem or outer supporting cylinder wall or both.

A coil compression spring has a smoother outer surface "of large radius curved coils" whereas the Belleville spring washer stacks are made up of thin washers "that each have a rough 90 degree edge to them". When Belleville washers are stacked together, these edges will rub on either the central supporting stem or outer supporting cylinder wall or both.

Belleville spring washers mated together have internal frictions caused by each individual coned surface rubbing upon each other as force flattens them. This can lead to inconsistency in pressure setting over time as the individual washers wear together.

Some Belleville spring washers will sit "cone edge" to "cone edge" but never 100% squarely.

Compression travel (of the Belleville spring washer stacks) is often limited and so wear and tear has a greater effect upon pressure output over time, as small adjustments make a large difference.

The reaction time (speed of compression / expansion) of the Belleville spring washer stacks are slower than it is for a one piece compression spring, due to all the internal friction of each and every individual washer.