Join Robert Lane as he delves into the world of airgun regulators – what they are, how they work and why they're essential for your shooting success. Our range of precision regulator kits cover most popular airgun brands and models, we also supply regulators for custom airgun builds so if you're unsure about availability, call us or send us an email. To view our selection, head over to our precision regulator kits page.

What is and why would you want to fit a regulator?

In reference to airguns, a regulator is used in the context of regulating air pressure within the outlet valve / firing valve chamber so as to stabilise muzzle energy and shot to shot consistency. The term airgun or air rifle regulator is therefore not a reference to a product that is used to raise / increase or boost an airgun / air rifle's muzzle energy, the regulator will only keep an airgun's muzzle energy (ft lbs / joules) to the power at which the firearm has already been tuned to at a set working pressure.

A mythical legend rumoured amongst nearly all airgun shooters, is that a perfect regulator will make every single shot you fire 100% identical and that fitting a good one will double your shot count!!!! This is indeed an absolute myth as all a regulator is "is simply a robust pressure switch" and all a regulator does "no matter what make or model you buy" is designate a pre-defined set working pressure to your airgun's internal workings as a whole (the intention being to fine tune your airgun to a specific choice of pellet). With this in mind, installing a regulator can really work wonders as long as the installer takes the time to balance the full outlet valve and firing mechanism correctly.

An airgun regulator is essentially, a very simple mechanical valve or switch (normally just the one but can have up to four moving parts) that operates when pressure in the regulated outlet valve chamber falls below a set pressure as the air gun is fired. Regulators / governors working upon surface area differential were first invented and put to use on steam engines in the industrial revolution (1700's). Their design and use has changed little over the years.

An airgun regulator will In general be one of two designs, either an opening and closing valve (valve opens itself with a drop in pressure then shuts with a rise in pressure) or a closing and opening valve (piston pushes open a valve when pressure drops and then closes it when pressure rises). The regulator is designed and set up so as to keep the air pressure in the outlet valve chamber at a constant pre set pressure, as the variable pressure within the main air reservoir chamber falls (as shots are fired).

You are using a regulator valve in your every day to day life that works on exactly the same principle as an airgun regulator but you just didn't know it! Most houses fitted with a gas supply or bottled gas use regulators. These are built into all the appliances such as cookers, water heaters etc. so as to give a constant safe working pressure. Interestingly most flush toilets have a valve (regulator) that works on exactly the same principles as all airgun regulators!

A PCP airgun in essence is quite a primitive mechanism, it has a high pressure air reservoir which is where the compressed air in the reservoir holds the energy. When you pull the trigger, a hammer (weight) is propelled forwards by a spring that simply hits the outlet valve pin, which opens a little and a small blast of the compressed air (Energy) escapes and propels your pellet down the barrel.

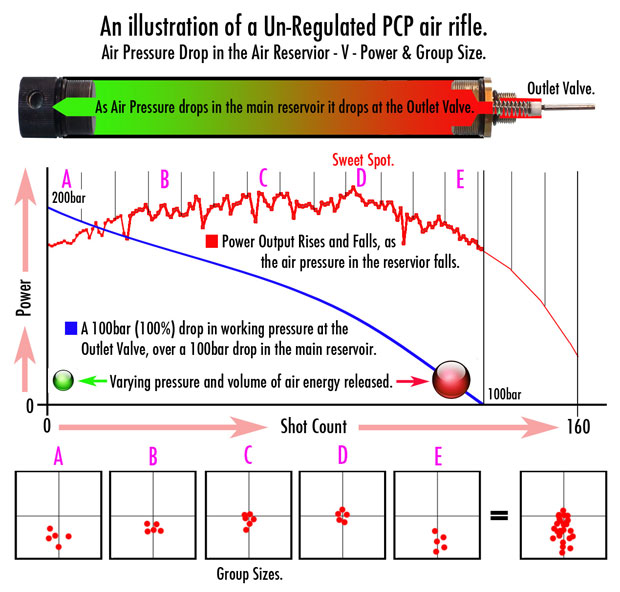

In a standard unregulated PCP airgun, you will normally fill the air reservoir to about 200 bar (2900 psi) and the last good shot being at about 100 bar (1450 p.s.i), so you can imagine with your first shot after filling to 200 bar (1900 p.s.i.) the hammer has to hit against and overcome 200 bar (1900 psi), so as to let out a little blast of air. Then by the point of your last shot the hammer only has to hit against 100 bar (1450 p.s.i) and so it lets out a bigger blast of lower pressure air.

The Spring that propels the Hammer stays constant and so does the Hammer Weight, and distance of Hammer travel, and so these forces are balanced out against the size of the Outlet Valve and the Outlet Valve Spring pushing the Outlet Valve Shut, so as the pressure in the air reservoir drops the energy released from the compressed air within the air reservoir is roughly constant.

However you will notice that this system is not perfect and power will alter over the 100bar drop in pressure in the air reservoir. This may be a slow constant fall in power, a slow rise then rapid drop of or most commonly a slow rise and fall - Curve / Arc.

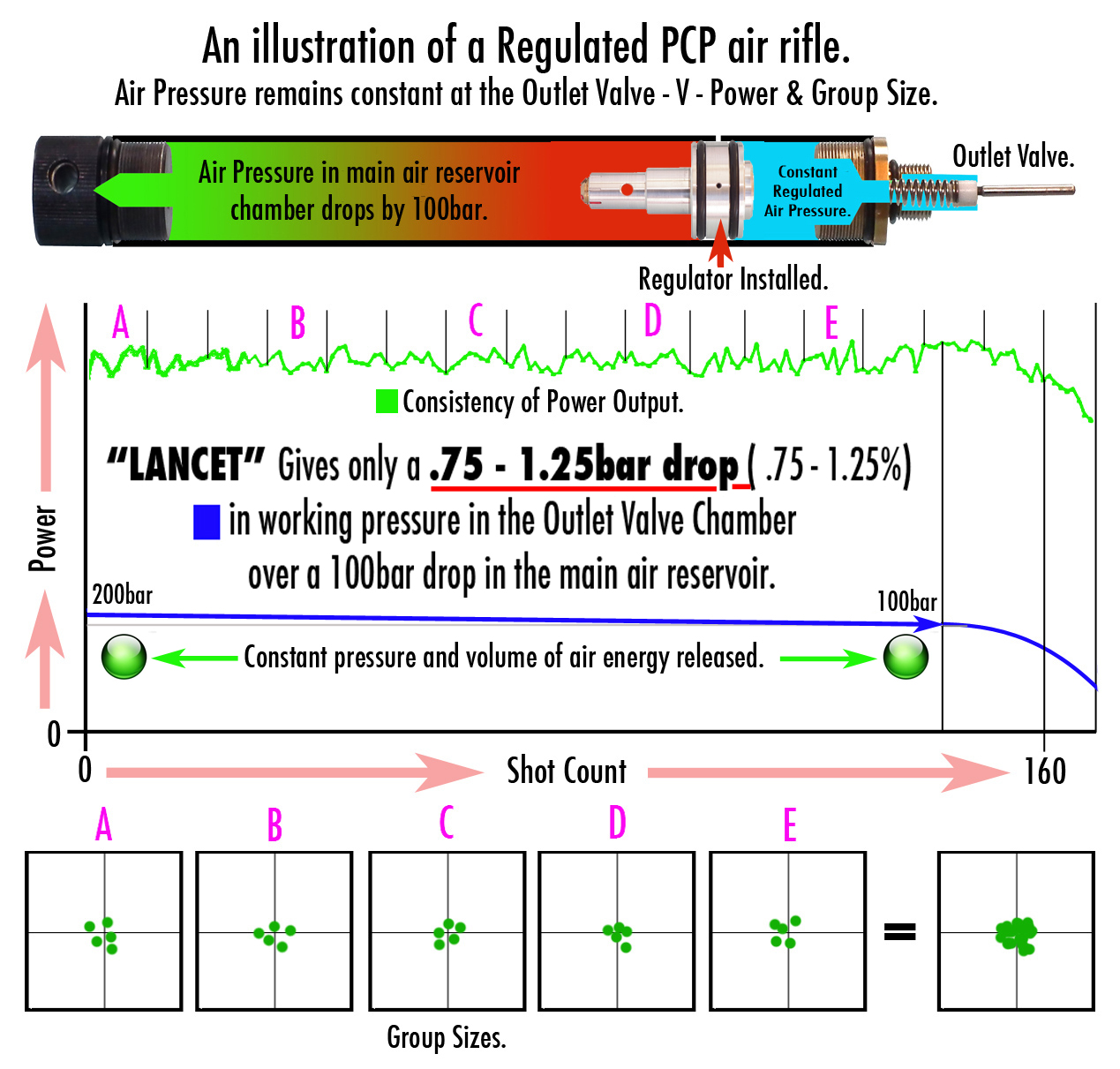

Installing a Regulator creates an Out Let Valve Chamber (Pre Chamber, Plenum Chamber), so dividing your air reservoir into two sections: The Main Air Reservoir Chamber which you fill up and the Outlet Valve Chamber, separated from the Main Air Reservoir Chamber by the Regulator. The high pressure air from the Main Air Reservoir Chamber enters into and through the Regulator, which only allows a constant set pressure to be stored in the Outlet Valve Chamber (Pre Chamber, Plenum Chamber).

So during every shot the Regulator valve opens and shuts and so keeps the pressure in the Outlet Valve Chamber (Pre Chamber, Plenum Chamber) constant for every shot, until the pressure in Main Air Reservoir Chamber is equal to or lower than the set pressure of the regulator.

By keeping the air in the Outlet Valve Chamber at a set constant pressure you stabilize your shot to shot (Feet Per Second / Meters Per Second) consistency at the muzzle. Which leads to greatly improved accuracy. It also means that the Outlet Valve Assembly can be tuned to use the energy stored within the compressed air far more efficiently.

Once a regulator is installed and the Outlet Valve Assembly re-balanced then you can in general use your rifle over a larger pressure range, this combined with the more efficient use of energy stored in the reservoir means that shot count remains the same for most high power air guns and some 12 ft/lb. rifles (Not ultra carbines) can experience a good percentage rise in shot count / Total muzzle energy expelled.

Greater efficiency of energy used means that there can also be a reduction in muzzle blast ‘Kick’ - ‘Flip’ and a reduction of muzzle noise ‘Blast’.

In summary

An airgun / air rifle regulator is nothing more and nothing less than a simple mechanical pressure switch. It does nothing more and nothing less than simply regulate air pressure upon the low pressure set side to a set pressure. The magic of having a regulator operating in your airgun / air rifle only happens when:

- It is Installed Correctly.

- The Outlet Valve / Hammer assembly is fully re-balanced correctly and the gun is used in combination with good pellet section.

This is no mean feet, especially for 10-15 ft/lb air rifles and if you are not mechanically minded or a patience, precise worker, setting about fitting a regulator may not be the project for you.